|

MeyerPlows.info |

Added 1-22-17

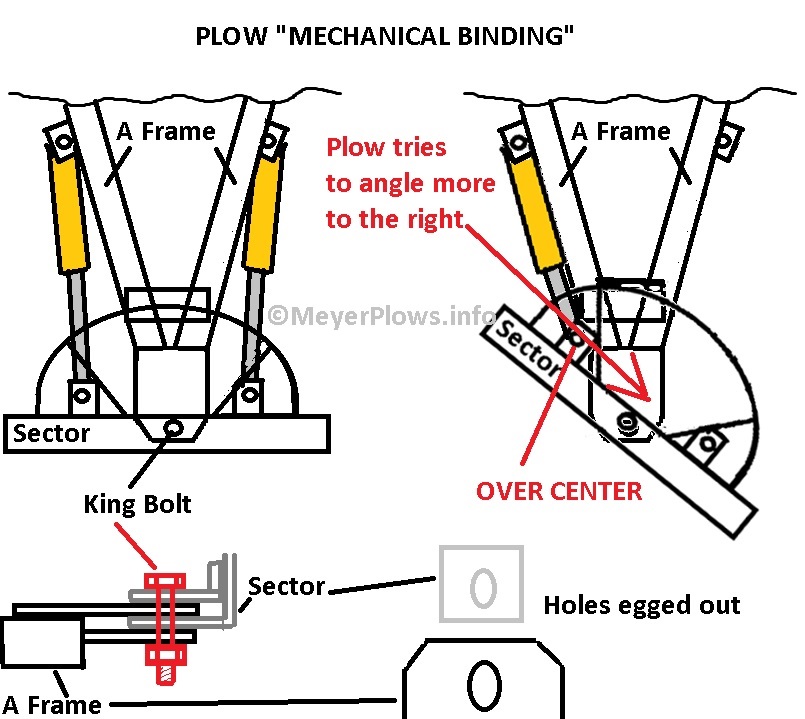

Mechanical Binding?

Mechanical Binding is mentioned (not using the term,

but it is what it means) in the Meyer plow troubleshooting flow

chart. The problem is that

unless something is bent or very "off" the plow will not bind when you PULL it

side to side.

The troubleshooting flow chart for "Plow willl not

angle left" says:

1. "Can the snow plow be angled by hand when the PA

Rams are disconnected from the A Frame?"

If YES

2. "Will the snow plow angle right and left if not

allowed to travel to extreme angle position?"

if YES

3. "Temporarily put 1/2" blocks between Sector andA

Frame to limit the degree of angle. Will the snow plow now

angle?"

If YES

4. "Weld 1-1/2" x 1-1/2" x 1/2" spacers to the A Frame

stops."

The problem with 1 above is that we just couple the PA

Rams together and see if we can move the plow by hand. This

is because once a plow is

experiencing mechanical binding the bolts holding the PA Rams on are not likely

coming out

without a

cutting torch. So we pull the plow side to side. It is not the same as the PA

Ram pushing in a specific place on

the Sector (the front bolt). So the result is the plow

does not bind. Even if we cut the bolts off, and removed the PA

Rams, the plow will not bind.

Again, because we are not pushing on that specific point to move the blade. The

picture below is not perfect, or to scale but you get the idea.

However, as you pull and push the plow, IF you look at that specific point, you

may notice the PA Ram going "over

center". In this case, when force is applied to the

front bolt, the plow is trying to angle MORE to the side it is already

angled to. This is because the

(angle of) PA Ram is over the center point, and it cannot extend more in the

direction it is

trying

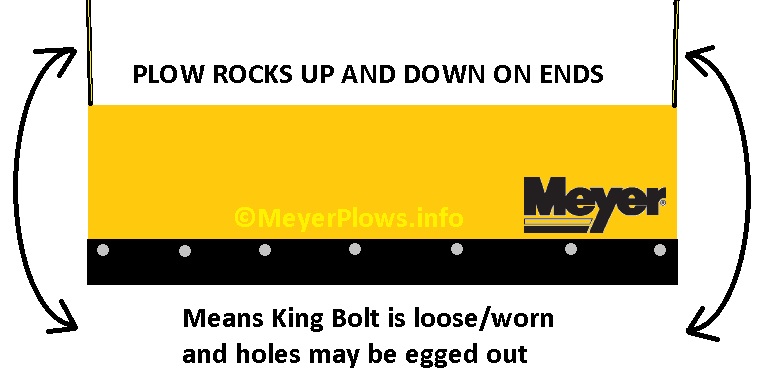

to go. As you move the plow back and forth by hand, look at the King Bolt. IF it

is rocking, spinning, or wobbling,

you likely have excessive wear to deal with. (Another

indication is if you raise the plow, go to one end and push down on

the top of the plow, it will

rock up and down a few inches, sometimes as much as 6").This can happen going

right or left,

it is

not specific to one side. Why does it happen?

Geometry. The plow is designed to pivot back and forth on the King Bolt. The PA

Rams extend and retract pivoting on

the front and back bolts. The back bolt holds the PA

Ram to the A Frame, and the front bolt holds the PA Ram (live end)

to the Sector. The King Bolt

passes through two holes in the Sector, and two holes in the A Frame. It is a

"knife" hinge

essentially. When these holes (in the Sector and A Frame) get worn, and even

egged out (oval shaped) instead of

round, this changes the geometry. Because in addition

to pivoting at this point, the Sector can oscilate. This oscelation

allows the Sector to move in

addition to just pivoting on the King Bolt, which in turn allows the live end of

the PA Ram to

go over

center. So once it is over center, it is tryingto angle MORE in the same

direction as it extends instead of the

opposite direction. So the plow gets stuck to one

side.

The fix is to remove the King Bolt (you will likely

need a torch), and weld the 4 holes round again. HOW you weld them

round matters as well. IF you

weld them wrong, in addition to not being able to get the bolt through the 4

holes, you can

change

the geometry instead of putting it back to where it was designed to be. In the

pictures below, the Sector is upside down.

As you

move the plow back and forth by hand, look at the King Bolt. IF it is rocking,

spinning, or wobbling, you likely

have excessive wear to deal with. Another indication

is if you raise the plow, go to one end and push down on the top

ofthe plow, it will rock up

and down a few inches, sometimes as much as 6". Once a King Bolt has been beat

on and hammered by being left loose for so long, you can rarely tighten it, or

even loosen the nut without a torch.

As originally designed, the

Sector rides under the "Sector Release Bracket" as it angles from side to side.

When the

plow is

straight, the Sector should be almost all the way under, touching the back of

the Sector Release Bracket. If it is

more towards the front, or partially out from under

the Sector Release Bracket, failure is close. In addition to the hole

being egged out, the hole in

the top nosepiece is likely cracked and spread open. This is one way you can

look at a

plow and know

how hard it was used, the position of the Sector in relation to the Sector

Release Bracket.

Back

to "IF you weld them wrong".... The object is to put the Sector and A Frame

Sector Release Bracket back to their

original position (Sector under the Sector Release

Bracket). I added a "Reference Line" to illustrate what would happen

if you welded it wrong. You

would move it more out from under the Sector Release Bracket.

The King Bolt is installed

from the bottom up, that is correct. It will not magically fall out, the nylock

nut will not let that

happen. Anyone who thinks theirs fell out, had sloppy holes in the Sector and A

Frame and the bolt finally sheared.

You can install it from the

top, but you will have to loosen ALL of the Trip Spring Eyes and tilt the plow

forward. You will

have

to do the same to remove or replace the King Bolt, after the Trip Spring Eyes

have been rusting in place for years.

IF it is installed from the bottom, it can be replaced

without loosening the Trip Spring Eyes.

The problem with the fix in

the Meyer Troubleshooting (#4 above) is that yes, it will stop the plow from

getting stuck, but

it

will not fix the real problem, it will allow the holes to get worse until the

plow breaks in two.

Here is a Meyer ST Series cracked Nosepiece, and

the repair.

Here is another Nosepiece that was caught before catastrophic failure.

How does the hole get egged out in the first place? MeyerPlowHelp.com - Post

_____________________________________________________________________________________________________

AUTHORIZED MEYER FULL LINE DISTRIBUTOR

|

Smith Brothers

Services, LLC |

|

|

Become a Fan of Smith Brothers Services on Facebook for up to the minute info! |

Entire site Copyright 2017 Smith Brothers Services, LLC All Rights Reserved

Our Other Sites:

Snowplowing-Contractors.com

ChucksChevyTruckPages.com

SmithBrothersPlowParts.com

SmithBrothersServices.com

MeyerPlowHelp.com MeyerST.com

PlowPump.info

MeyerPlowPumpParts.com

Home-Plow-By-Meyer.com MeyerE-57.com

MeyerE-60.com

MeyerDrivePro.com

MeyerPlows.info MeyerLotPro.com

MeyerE-47.com

MeyerRoadPro.com

SmithBrothersTruckParts.com

MeyerE-58H.com MeyerPathPro.com

MeyerVPlow.com

MeyerE-72.com

Smith

Brothers Services on

YouTube MeyerE-68.com

Author: Chuck Smith

Common Misspellings: Meyers, Mayer, Mayers, Myer, Myers, Maier, Maiers, Meijer.